-

Products

-

Back to Previous

- All Products

-

Storage & Logistics Equipment

- All Products

-

Featured Products

Featured Products

Back to PreviousFeatured Products - Used Products

-

Racking & Storage Systems

- All Storage Systems

-

Racking Inspections and Repairs

Racking Inspections and Repairs

Back to PreviousRacking Inspections and RepairsInspections By SEMA Accredited Inspectors

All Inspection Services![]()

- Safety, Process & Maintenance

-

Warehouse Transfer Rentals

Warehouse Transfer Rentals

Back to PreviousWarehouse Transfer RentalsMoving? Explore The Benefits Of Renting Through Us

How We Can Help Moving Warehouse![]()

-

Rental Equipment

- Equipment To Rent

-

Manufacturing

-

Plastic Box Manufacturing

Plastic Box Manufacturing

Back to PreviousPlastic Box ManufacturingPlastic Box Manufacturing

Explore Plastic Box Manufacturing![]()

-

Roll Pallet Manufacturing

Roll Pallet Manufacturing

Back to PreviousRoll Pallet ManufacturingRoll Pallet Manufacturing

Explore Roll Pallet Manufacturing![]()

-

Stillages Manufacturing

Stillages Manufacturing

Back to PreviousStillages ManufacturingStillages Manufacturing

Explore Stillages Manufacturing![]()

-

End-to-End Service

-

The Full Product & Service Offering

The Full Product & Service Offering

Back to PreviousThe Full Product & Service OfferingExplore The Efficiency Savings of a Single Provider

Explore How We Can Save You Money![]()

- Rental

- Industries

- About

- News & Insights

- FAQs

- Contact us +44 0161 905 2233

- Home

- News & Insights

- Managing Inventory Through End-To-End Warehouse Storage Solutions

Managing Inventory Through End-To-End Warehouse Storage Solutions

- Blog

As businesses increasingly seek strategies to optimise processes and adapt to changing customer demands, warehouse management presents a number of improvement opportunities. Efficient warehouse management is a key factor to ensure seamless supply chain operations and remain competitive.

From a supply chain perspective, comprehensive storage and logistics solutions offer businesses an overall approach to enhancing warehouse efficiency. End-to-end warehouse storage and logistics equipment provide the infrastructure and products needed to maintain efficient operations and meet customer expectations.

Having recently acquired West Pennine Storage Equipment, Yorkshire Storage Equipment and Astirvant, racking and workplace solution companies, we have strengthened our position, now offering a complete range of warehouse storage and logistics solutions.

End-to-end warehouse storage solutions are a comprehensive approach to managing warehouse operations, from initial storage facility setup to ongoing logistics and inventory management. These solutions encompass a range of equipment designed to optimise storage, handling and distribution processes.

The Role of Racking & Shelving in Warehouse Efficiency.

Racking and shelving systems lay the foundation for a warehouse and provide the backbone for organised and accessible inventory management. These systems must be designed for space optimisation and support the seamless flow of goods from receipt to dispatch in a warehouse setting.

By implementing these systems, warehouses can optimise vertical space, allowing for a higher volume of goods to be stored in a smaller footprint. Utilising the vertical space in a warehouse allows businesses to store more goods with the same footprint, reducing the need for additional storage facilities.

Maximising space not only helps to avoid the cost of facility expansion but also streamlines inventory management by making it easier to locate and retrieve items quickly.

Tailored solutions, specific to the needs of a business’s operations, offer significant benefits by accommodating diverse product sizes and weights as well as enhancing operational flexibility. Customisation supports efficient picking, loading, and dispatching processes by ensuring that frequently accessed items are stored in easily reachable locations, reducing retrieval times and minimising handling errors. Bespoke solutions integrate seamlessly with automation technologies, further improving speed and accuracy in order fulfilment.

Additionally, these systems contribute to improved safety and reduced handling times, as items are securely stored and accessible, minimising the risk of accidents.

The importance of storage equipment in warehouse management.

Effective warehouse management also heavily depends on strategically utilising storage equipment such as roll cages, roll pallets, plastic boxes and stillages. All playing a crucial role in enhancing operational efficiency and reducing costs.

These tools aid in precise stock control by enabling easy movement and accurate inventory organisation. Logistics equipment allows for efficient transport and temporary storage of goods, helping warehouses maximise their available space for improved inventory management

Storage equipment such as plastic boxes are vital for protecting fragile or perishable items during handling and transit, ensuring they remain in optimal condition and reducing waste. As well as this, plastic pallets are stackable to ensure even further space utilisation.

Incorporating these types of equipment into warehouse operations, businesses can streamline processes, reduce unnecessary expenses, and drive efficiencies across the supply chain, resulting in significant cost savings.

Adapting to market demands with comprehensive storage solutions.

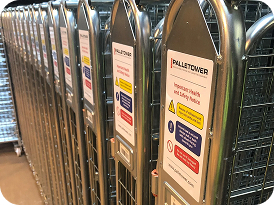

In today’s dynamic business environment, Palletower stands out as a global leader in world-class storage solutions for warehouse management.

To quickly adapt to a market demands, your suppliers need to be flexible and customisable to diverse industry needs. Whether it’s retail needing rapid stock turnover, food and beverage requiring temperature-controlled storage or manufacturing needing durable, flexible racking, every industry requires solutions to ensure smooth operations, optimise space, and meet customer expectations.

Focusing on efficient inventory management, through world-class storage and logistics equipment, Palletower empowers businesses to achieve cost savings, streamline supply chain processes, and adapt seamlessly to ever-changing market demands. Our recent acquisitions further solidify their ability to deliver tailored solutions that cater to diverse industry needs.

Effective inventory management in the warehouse relies heavily on the synergy between racking and storage equipment.

Racking plays a foundational role in organising warehouse space with storage and distribution equipment complimenting warehouse operations.

In unison, these systems create a seamless, scalable and highly efficient operation. Leveraging the services of Palletower, an end-to-end warehouse storage and logistic solution provider, can ensure a well-organised and responsive warehouse environment, leading to better customer service and operational success.

Have Any Questions?

For more information on any products or services we offer, please visit our Contact Us page or call 0161 905 2233 where we can answer any questions or queries.

Contact Us